PRODUCTS

High Frequency Board Manufacturing Tips

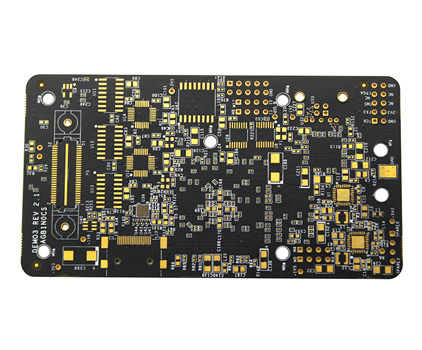

High-frequency boards (HFBs) are the backbone of modern communication systems, powering everything from 5G networks and radar systems to high-speed data centers and advanced medical imaging equipment. Their ability to handle signals in the gigahertz range demands meticulous design and manufacturing processes. The slightest imperfection can significantly impact performance, leading to signal attenuation, impedance mismatches, and ultimately, system failure. Therefore, understanding the intricacies of high-frequency board manufacturing is critical for ensuring optimal performance and reliability. This article delves into key aspects of manufacturing these sophisticated circuits, offering practical tips to improve efficiency and achieve superior results.

Material Selection: The Foundation of High Performance

The choice of materials is paramount in HFB manufacturing. Standard FR4 substrates, commonly used in lower-frequency applications, are often unsuitable due to their high dielectric loss and relatively poor thermal conductivity at high frequencies. High-frequency applications demand materials with low dielectric constant (Dk) and low dissipation factor (Df) to minimize signal loss and ensure signal integrity. Popular choices include Rogers RO4000 series, Taconic RF-35, and Arlon 25N, each offering different properties tailored to specific needs. Careful consideration must be given to the intended frequency range and the desired impedance characteristics when selecting the appropriate substrate.

Beyond the substrate, the choice of copper foil also plays a crucial role. Thinner copper foils, often found in HFBs, provide lower resistance and inductance, improving signal transmission. However, thinner foils are more susceptible to damage during manufacturing. Manufacturers should consider using heavier copper foils in areas where mechanical stress is expected, or employing specialized techniques like plating to enhance durability. The copper's surface roughness can also influence high-frequency performance, with smoother surfaces minimizing signal loss.

Layout and Design: Minimizing Signal Degradation

Effective layout design is crucial for minimizing signal degradation in HFBs. Careful planning of component placement, trace routing, and ground planes is essential to maintain signal integrity at high frequencies. Factors such as trace width, length, spacing, and bends directly impact impedance and signal reflections. Computer-aided design (CAD) software with built-in electromagnetic (EM) simulation capabilities is invaluable in optimizing the layout and predicting signal behavior before manufacturing.

The use of controlled impedance traces is critical. Maintaining a consistent impedance along the entire signal path prevents reflections and signal distortion. This requires precise control over trace width, thickness, and spacing from the ground plane. Careful consideration should also be given to the placement of vias, which can introduce inductance and capacitance that disrupt signal integrity. Techniques like using smaller vias and employing multiple vias to reduce inductance can be employed.

Manufacturing Processes: Precision and Control

High-frequency board manufacturing requires precision and control at every stage. The fabrication process itself can introduce unintended changes in the impedance and introduce signal losses. Methods like laser drilling for vias offer superior precision compared to mechanical drilling, leading to better impedance control. The quality of the solder mask and the accuracy of the plating process are also critical to ensure reliable connections and minimize signal leakage.

Automated optical inspection (AOI) and other quality control measures are crucial to identify defects early in the manufacturing process. These techniques help to detect errors such as opens, shorts, and misaligned components, preventing costly rework and improving overall yield. Implementing robust quality control procedures and regularly calibrating manufacturing equipment helps to ensure consistent high-quality production.

Testing and Verification: Ensuring Optimal Performance

Rigorous testing is indispensable to verify that the manufactured HFB meets the required specifications. High-frequency testing involves measuring parameters like impedance, return loss, insertion loss, and crosstalk across a wide range of frequencies. Specialized equipment like network analyzers and time-domain reflectometers (TDRs) are essential for accurate measurements.

Once the boards are manufactured, thorough testing should be conducted to validate the design and manufacturing process. This may involve testing individual components, sub-assemblies, and the complete system to ensure performance meets the expected criteria. Any deviations from specifications should be thoroughly investigated and corrective actions implemented to prevent recurrence.

In conclusion, the successful manufacturing of high-frequency boards relies on a holistic approach that considers every aspect from material selection to final testing. By implementing these tips and adopting best practices, manufacturers can significantly improve the quality, reliability, and performance of their HFBs, paving the way for the development of more advanced and sophisticated electronic systems.

SUBSCRIBE

INQUIRY